Z80 RC Conversion Quick Start Guide

RC conversion of foam gliders is a great program for user to learn fly. But before you start, you need to know that it’s a systematic project that requires patience and skills.

Warning

- It's only for users over 14 years old.

- There are many options for the 860mm glider conversion and they follow roughlythe same basic steps.

- This guide is a 3-channel twin motor program, please read it carefully before you start.

- Parts, tools and accessories required for this program may not be included in the package.

- The workmanship will affect the flight performance of the plane.

- This is a quick start guide, please go through www.hawks-work.com/pages/860rc for more details.

- if you need support or have any feedback, please feel free to contact us via email support@hawks-work.com.

Part 1 Recommended Parts List

-

This is a general recommendation and you can adjust it to your needs.

-

-

Part 2 Converse Wing

-

2.1 Make ailerons

-

-

Cut the ailerons along the lines.

-

-

-

-

Turn to the back and cut about 90° for aileron movement.

-

-

-

-

Fix the aileron with tape.

-

-

2.2 Cut the room forservo and ESC

-

Groove the back of the main wing.

You need to adjust the size according to your servo and ESC dimensions.

-

-

2.3 Mount servo and motor

-

CW is the motor with holes and mounted on the right side. CCW is the flat motor and mounted on the left side.

Use hot melt glue to fix the motor base, then secure the motor to the base with screws.

-

-

-

-

-

Caution:

The motor needs to distinguish between left and right. Please install them as suggested, otherwise the subsequent soldering will not be the same.

Use quick-drying glue to fix the servo and control horn.

Part 3 Converse Fuselage

-

3.1 Remove hatch cover

-

-

3.2 Make quick-releasestructure

-

Cut along the line.

-

-

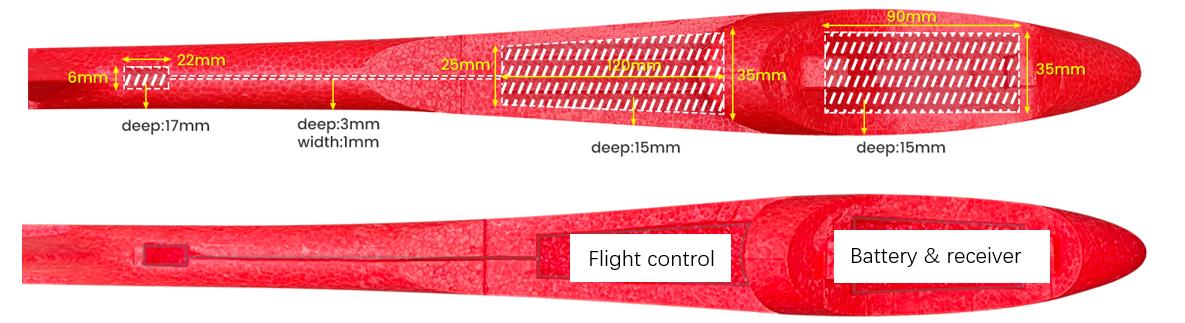

3.3 Cut the battery compartment and flight control compartment

-

Openingup these two compartments.

-

-

3.4 Cut servo holes andwire channel

-

-

3.5 Mount the servo

-

Part 4 Converse Horizontal Tail

-

4.1 Make the elevator

Cut the elevator rudder along the line and then cut to make it movable.

-

-

-

-

-

-

4.2 Cut vertical fin& insert horizontaltail

-

-

-

-

4.3 Install servo and control horn

-

-

-

Part 5 Converse Canopy

-

5.1 Remove the counterweightscrews

-

-

-

5.2 Cut the battery compartment

-

Because the battery and receiver are different sizes, you should cut a proper space.

Part 6 Connecting Circuits

-

6.1 Warnings

(1) A soldering iron is required and this guide does not provide relevant instructions.

(2) Check that there is no problem with the circuit before connecting the battery.

(3) For safety, do not install propellers in this part.

(4) It is recommended that novices use the flight control. But because different flight controls are connected differently, here is wiring for no flight control.

-

6.2 Schematic

-

-

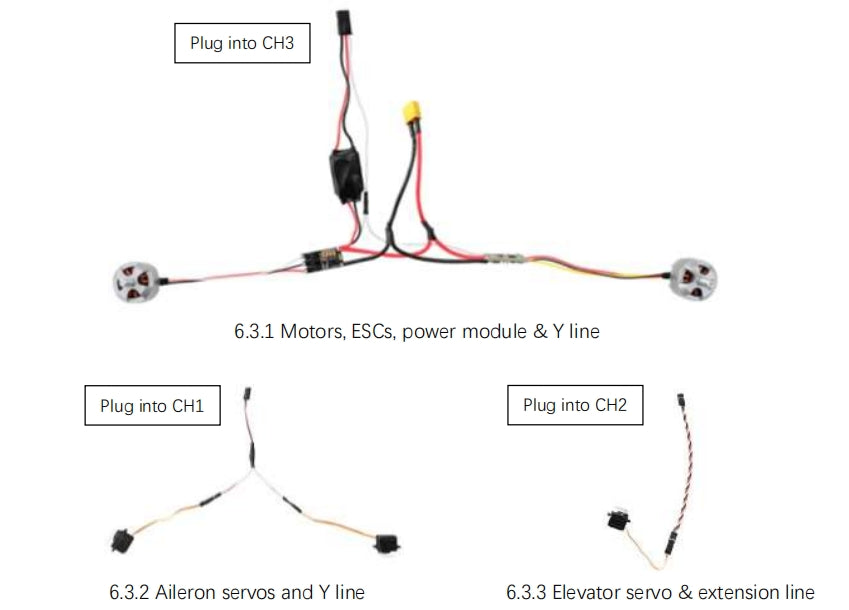

6.3 Wiring

-

If in 2.3 you follow our advice of mounting the CW motor on the right side and the CCW motor on the left side. You can refer to this picture to solder.

But if you want to change the motor rotation direction, you just exchange any of the 2 wires.

-

6.4 Caution

(1) In practice, we recommend minimizing the use of plugs, because plugs may come loose and are not very stable.

(2) Besides, soldering reduces the weight, the lighter the airplane the easier it is to fly and control.

(3) After the circuit is soldered, it needs to be insulated.

Part 7 Check & Calibrate

-

7.1 Warning

To be safe, don't install the propeller until you have to.

-

7.2 Check the initial position of the servos

Unscrew the servo and control horn, then plug into the battery, the servo will return to the initial angle. Adjust the horn and then tighten the screws.

-

-

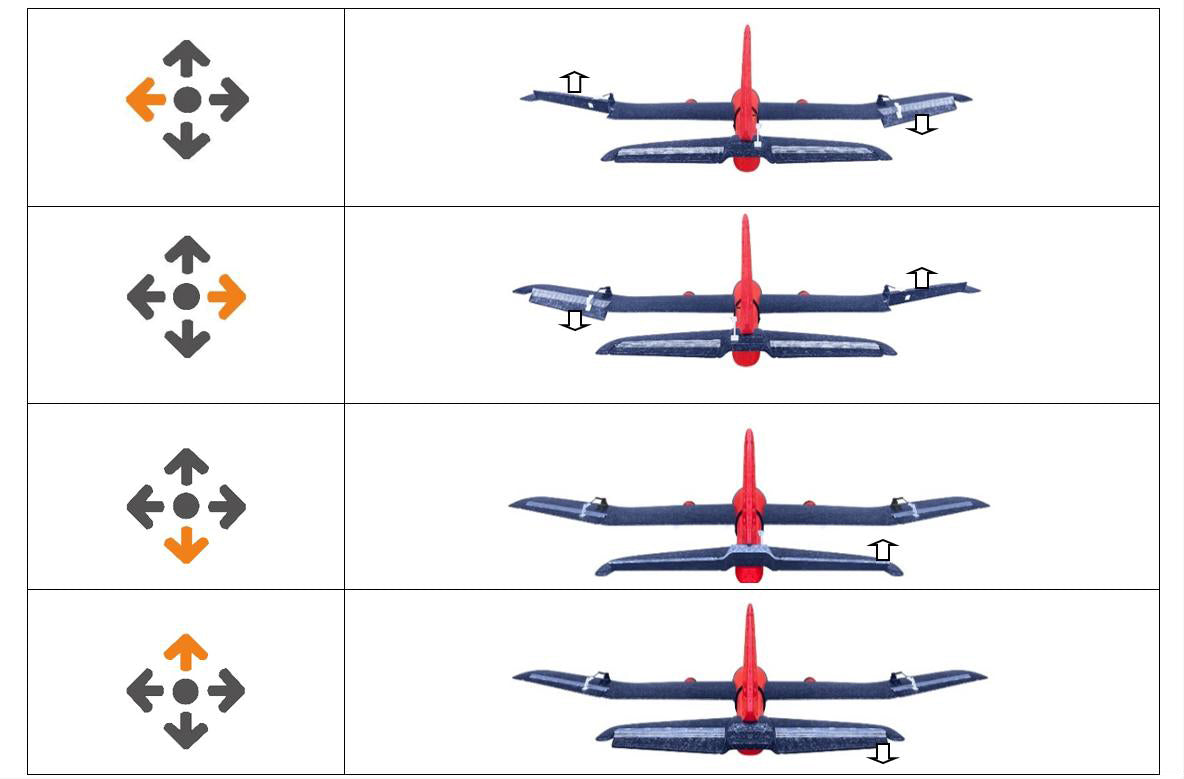

7.3 Check aileron and elevator

You need to sync your transmitter with receiver first. Then check the servo direction by using the joystick.

-

If it is not correct, you need to change the set of your transmitter.

-

7.4 ESC calibration

Steps:

Turn on transmitter - Push throttle to top - Plug in battery - ESC makes sound “didi” - Pull throttle to bottom - ESCs makes short and long sound (or a piece of music) - Complete

-

7.5 Check the direction of motor rotation

If the direction of rotation is incorrect, adjustments must be made. You can reverse the motor rotation by changing any 2 wires soldered to the ESC.

-

-

7.6 Install props

The props are differentiated between left and right, and the prop marked with R need to be mounted on a CW motor (hole).

Use pliers to tighten the screws to prevent the props from falling out.

-

7.7 Adjusting the Center of Gravity

The center of gravity of an airplane should be at 1/3 of the front edge of the wing; an airplane with a proper gravity center fly more smoothly.

-

-

Usually, we adjust the center of gravity by battery. In order to get better weight allocation, we adjust the position of the battery or replace the battery with proper weight.

After finding the right position, we need to fix the battery to avoid it moving during flight.

-

7.8 Secure the plane and tidy up the wires

Pair text with an image to focus on your chosen product, collection, or blog post. Add details on availability, style, or even provide a review.

-

Secure the front part the quick release structure by hot melt glue. Be sure to wait for the glue to fully set before proceeding to the back.

The lines on the surface of should be held in place with tape.

Part 8 Fly

- All previous work must be done before flying.

- We still need to optimize the aircraft in test flights.

- Users don't have fly experience should first practice with a flight simulator.

- User should comply with local laws and regulations.

- Flights should be kept away from crowds, buildings and trees.

- It may take some time to become a good pilot.

Part 9 Others

- This manual is a twin motor RC conversion program. If you want to try otherprograms such as FPV carrier, vertical take-off fixed-wing (VTF), long range, highspeed, etc., you can search on internet or explore on your own.

- Problems caused by improper cutting during the conversion process are notcovered by the free aftermarket warranty.

- Loss or breakage of the plane in flight is not covered by the free aftermarketwarranty.

- If you have comments and suggestions, please send an email to support@hawkswork.com, We welcome any advice and correction from our users.